Model:

Specifications

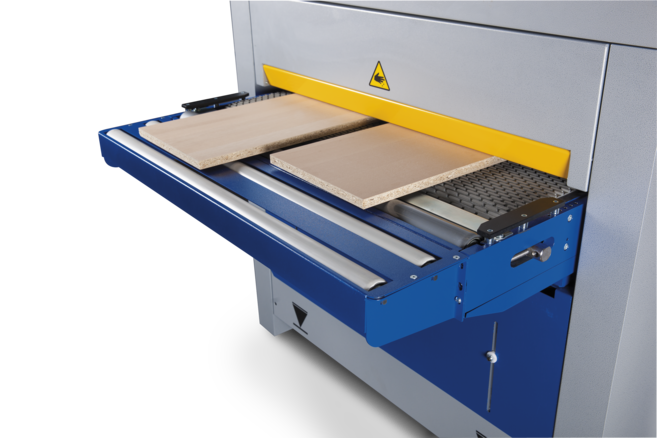

The optimal arrangement of the two processing units in the FW 1102 classic makes it possible to carry out pre and fine sanding in one single process, offering increased productivity.

Additional belt changes like those required with a single belt machine are not necessary.

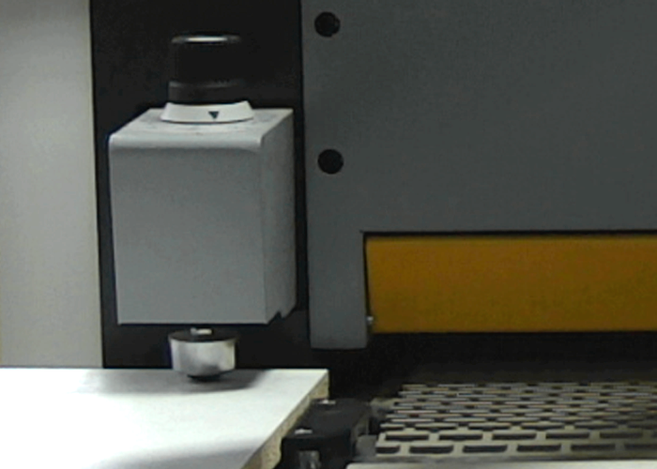

Standard equipment such as electronically controlled conveyor feed, hand safety stop and stop to ensure that oversized pieces cannot be fed through, powerful motors, mechanical suspended pressure rollers and an absolute vibration-free power transmission to the sanding aggregate guarantee reliablity and an excellent sanding finish.

Highlights:

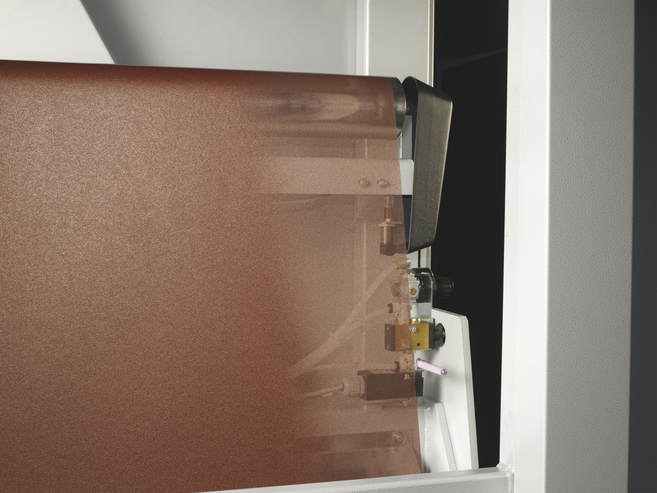

Powerful combination aggregate with electro-pneumatic sanding shoe

Productive control panel control, precise grain equalisation

FELDER operating comfort: electrical height adjustment with digital display

Excellent results on veneered

workpieces

Automatic inverter control of

the feed speed

Feeding belt control, hand safety stop and stop to ensure that oversized pieces cannot be fed through, ensuring optimum operating safety

Vibration-free power transmission from the 20 hp sanding belt motor